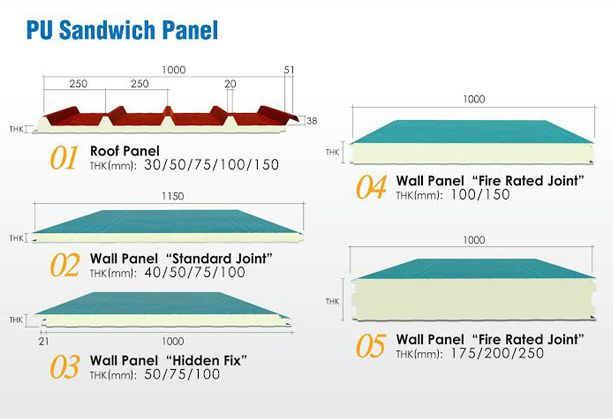

We provides wide range of steel, aluminum and stainless steel faced sandwich panels with polyurethane core marker with CS trade name. The range of products includes wall and roof sandwich panel for industrial hall, sports halls, housing, warehouses, production facilities and public utility buildings. The thickness of panels ranges from 25mm to 250mm.

There are two types of polyurethane core used in production of CS panels: PUR and PIR foams. Polysocyanurate PIR foams are characterized by improved resistance to high temperature. Flat bonds of PUR foams decompose in approximately 200°C, and carbonization in combustion is only 20%. Isocyanurate structures in PIR foams decompose in temperature approximately 325°C and carbonization reaches up to 50%. Significant carbonization of PIR foam constitutes a barrier for spreading of fire due to low thermal conductivity of carbonized layers and resistance to oxidation. This way the material from deeper layers of PIR foam is protected from combusition, and the carbonized layer prevents high temperature from combustion, and the carbonized layer prevents high temperature from passing throught sandwich board. As a result, greater fire protection is achieved.

We are fulfilling high requirements concerning thermal insulation, high load bearing capacity and rigidity with wide range of acceptable temperature differences of outside and inside claddings. It enables application of considerable spans of supports both in the ceiling and on the walls at the same time.

Joint Type

Download Brochure:

Go Back

Back to Top